Project Management

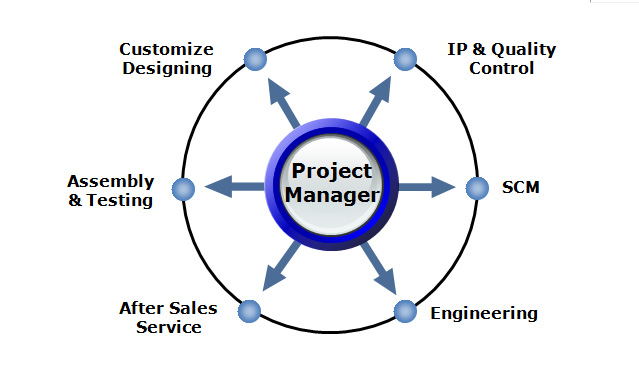

We established professional project management team, to take over the whole process from sample to batch for the processes control and design change verification, supervise relevant departments to carry out improvement and optimization for structure and process, as well as the analysis and solution of abnormal problems during production process. To ensure effectively implementation of project, we practice APQP group Performance appraisal mechanism, and put forward the assessment recommendations to the project related departments to ensure that the project objectives are consistent with company’s business objectives.

Through application of knowledge, skills, tools and techniques to project activities to meet project and customer requirements. Organizing and managing resources to complete project within defined scope, quality, time and cost constraints.

Key Performance Indicator(KPI):

- Effective project management processes;

- Identify risks and opportunities;

- Project tied to the organization`s business goals;

- Senior management commitment;

- Define requirements in detail;

- Realistic schedule and clear directions;

- Good Stakeholder relationships;

- Skilled and appropriate team members with defined roles and responsibilities;

- Make contingency plans;

- Set clear performance expectations;

- Communication objectives frequently.

NPI

Our program team coordinates all new product activities, from identifying improvement for Design for Manufacturability (DFM) to cost optimization to development of manufacturing and control plans to material tracking and part expediting to final first article submission.

Establish standard procedures and regulate work approach of project engineers to ensure the smooth transition from sample to mass production, provide effective technical support for mass production, along with all related controlled information and dwgs for production and quality department. Ensure that all project complete as schedule.

We have product operation center, communication mechanism for NPI team with customers and suppliers, adopt product liability system, ensure to provide good service and strong support for customers and suppliers.

Roles and Responsibilities:

- MSA analysis, confirm the analysis and resolution capability of the measurement system;

- Confirm needs for special characteristics material;

- Machining process;

- Manufacturing hours and cost analysis;

- Technical analysis and control and solutions;

- Applicable equipment and tooling, error proofing technology implement and identification;

- Work instructions;

- Packaging specification;

- Inspection methods and approval criteria;

- The qualified rate of the product.